Sorting hooks are not your typical everyday hook for most companies, but for those companies and individuals who use them, and whether you call them lay out hooks, pelican hooks, shake out hooks, or sorting hooks, a little refresher on correct application may be in order.

The sorting hook was manufactured for the intended use for sorting and laying out plate, pipe, cylindrical shapes, and other items that allow engagement to the full depth of the hook throat in multiple sling leg applications.

Although hooks for overhead lifting are required to be equipped with a latch, whenever practical, the presence of a latch would significantly limit the practical use of the sorting hook when lifting plate and cylindrical shapes such as pipe.

Keep these application points in mind:

-

The sorting and laying out process includes moving these materials at a height close to the ground with the load and load connections visually observable by the crane operator throughout the entire load handling activity.

-

The hooks must be attached in a manner which will maintain a level, balanced and stable condition throughout the entire process.

-

If the load exhibits obvious bending, the lift must then be immediately stopped for analysis and evaluation to ensure safety.

-

During the load handling activity, the slings with hooks at the load connections must remain under tension at all times to prevent any of the hooks from disengaging.

-

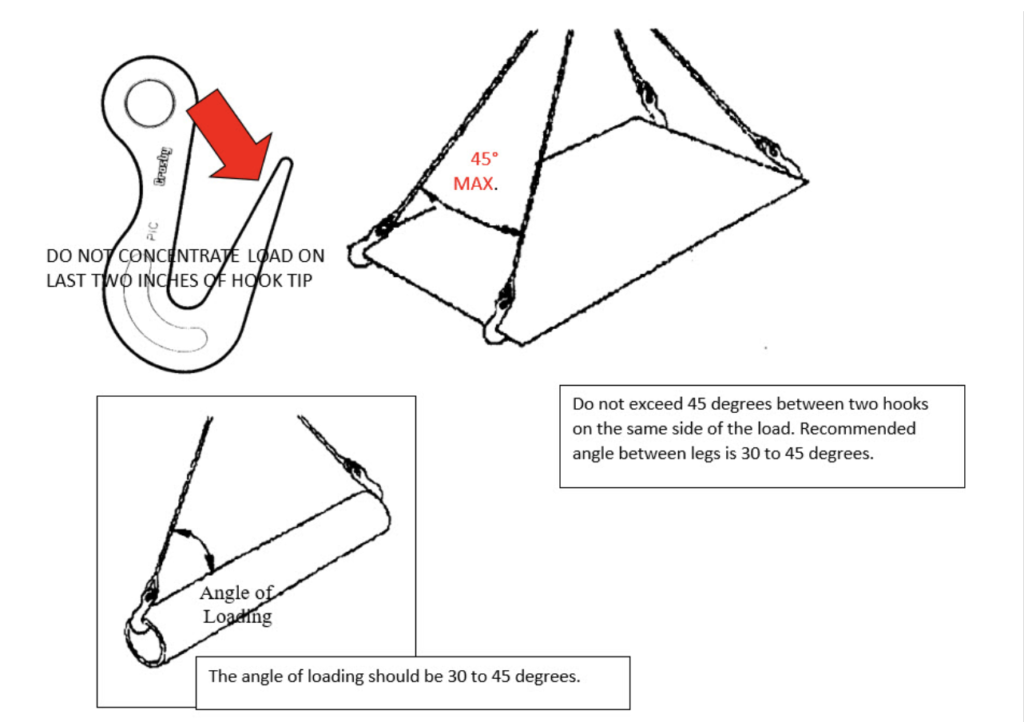

It is also important to recognize that the load on the sorting hooks will vary depending on the angle of loading. When the angle of loading is 30 to 45 degrees, and the load is inserted to the full depth of the hook throat without creating tip loading the working load limit for the Crosby sorting hook is 7.5 tons. If the angle of loading is greater than 45 degrees, possible tip loading may occur and the maximum working load limit is reduced to 2 tons, when the hook is fully engaged.

Some additional points to consider:

-

Never concentrate loading on the last 2 inches of the hook tip.

-

Never exceed 45 degrees “included angle” between two sling legs that are on the same side of the load. Exceeding 45 degrees may result in the slings slipping along the load surface.

-

The recommended angle of loading when using sorting hooks is 30 to 45 degrees. These lower angles, although typically discouraged for most rigging applications, allows the load to more easily obtain full hook throat engagement.

-

When the angle of loading is greater than 45 degrees, tip loading and failure to obtain full hook throat engagement is very much a concern.

-

Sorting hooks are for straight in-line loading only. Side loading applications are not allowed.

-

Calculate the sling tension and know the loading in all connection points to ensure all rigging gear is sized appropriately.

-

Never exceed the working load limit as stated on the sling identification tag. Remember, sorting hooks are used in multiples, such as two-, three-, or four-leg wire rope sling assemblies. All slings require proper identification including capacity of the sling assembly.

The sorting hook was manufactured for the intended use for sorting and laying out plate, pipe, cylindrical shapes, and other items that allow engagement to the full depth of the hook throat in multiple sling leg applications.

Rig Safe!

– Danny

Danny’s Rigging Den is a blog series written by Danny Bishop, Crosby’s corporate director of value added training.

No Comments Yet