Having championed the role of the rigger and emphasizing the value of professionals who attach equipment that lifts, moves, or secures complex, critical, and heavy objects in one of my last posts, it’s timely to drill down into the sector a little deeper to examine some of the things that should be considered while gathering the facts needed to construct a solid plan before commencing the load handling activity (LHA). Plan ahead and think it through because lives and loads are at stake.

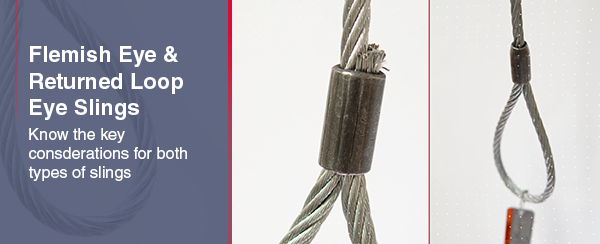

Read MoreKey differences between Flemish Eye & Returned Loop (Turn Back) Eye Slings

Danny Bishop compares two common types of wire rope slings.

The two most common types of slings used in material handling applications using single part six-strand wire rope are the mechanical spliced Flemish Eye Sling and the mechanical spliced Returned Loop Eye Sling. Some people call the Returned Loop Eye Sling a Turnback Eye Sling.

Read MoreShackles 101

Understanding the different types of shackles – the industry workhorse – with Danny Bishop

A shackle is a U-shaped steel connector with holes drilled into the ends for receiving a removable pin or bolt. Shackles are commonly used to connect the slings or load to a winch or crane block, for example. It is one of the most powerful, important, irreplaceable pieces of material handling equipment there is. The shackle “bow” is a word that refers to the U-shaped body of the shackle.

Read MoreImportance of initial inspections

As we continue to pioneer the advancement of industry best practices below-the-hook, Danny Bishop reiterates the importance of pre-use inspection.

Most riggers are aware of the need to inspect their slings and rigging hardware every day, before and during their use, which is sometimes called the in-service or frequent inspection. And riggers are normally aware of the need for a thorough inspection, which is sometimes called the periodic inspection, that is required by many standards a minimum of once per year.

However, there is a critical inspection that is often overlooked or ignored by many companies in the various material handling industries, called the initial inspection.

Read More