Our customer needed to recover 10 off 140mm ground wires that had been abandoned in a water depth of 110 meters. The wires were situated on the seabed, with one end connected to a drag embedment anchor and the other end free. The most suitable method for this operation would be to employ a wire grapnel to retrieve the wires.

THE CHALLENGES

– Standard grappling equipment was designed with pockets of only 120mm.

– The customer specified a requirement for double fluke engagement with the wire rope. However, due to the wire curvature in this formation, the pockets of a standard grapnel would need to be significantly increased.

– The equipment had to be on-site in 12 weeks.

– Considerations had to be made regarding the operational loading of the grapnel while submerged, as well as the forces exerted during deployment and recovery over the stern rollers of the vessel.

SOLUTION

– Aligning both our engineering and operational teams with the customer provided us with clear understanding of the precise deliverables.

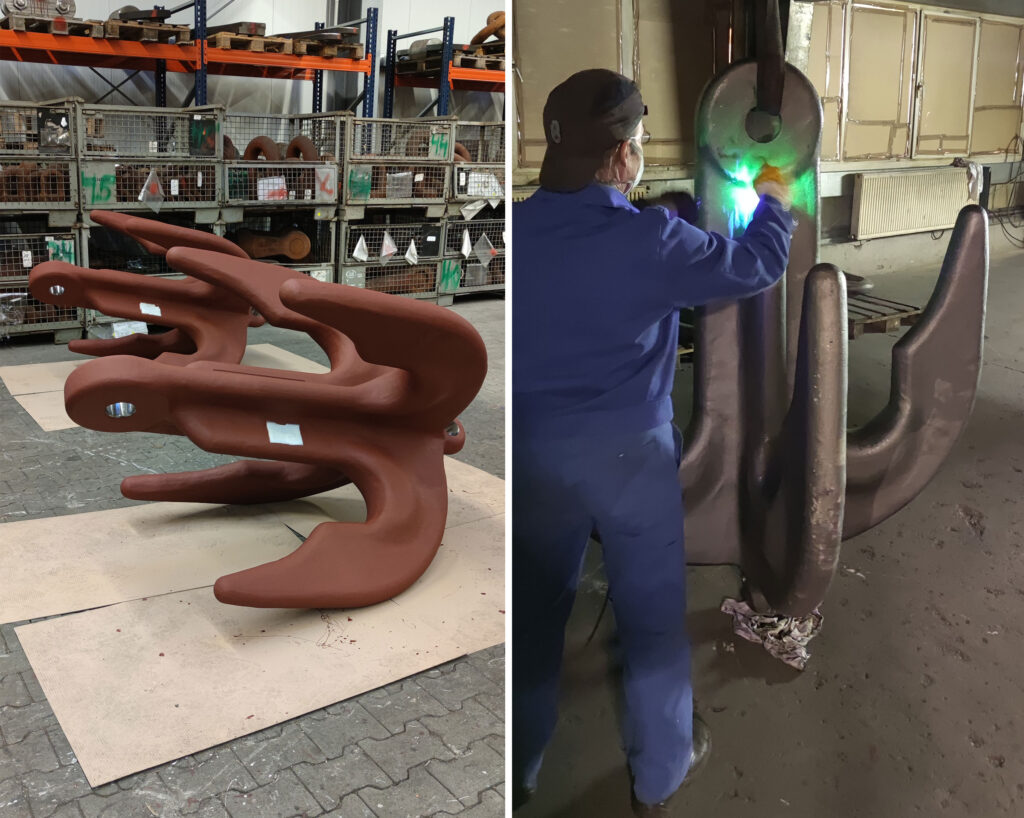

– Because all Crosby Feubo chasing equipment is cast, this allowed for the re-engineering of a conventional grapnel, resulting in an increased pocket width from 120mm to 230mm.

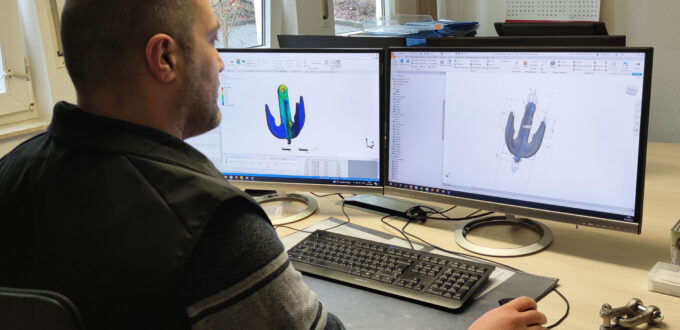

– By utilizing 3D modeling and FEA techniques, we successfully redistributed redundant material to areas with higher stress in the new design.

– This approach enabled us to make minimal changes to the weights and overall dimensions of the unit, while maintaining maximum strength and durability.

RESULTS

Two units were delivered on budget and ahead of schedule with a comprehensive certification package. The innovative grapnel design allowed for successful recovery of the subsea anchor lines, demonstrating the engineering proficiency of Crosby Feubo products and Crosby’s ability to provide specific solutions for customers.