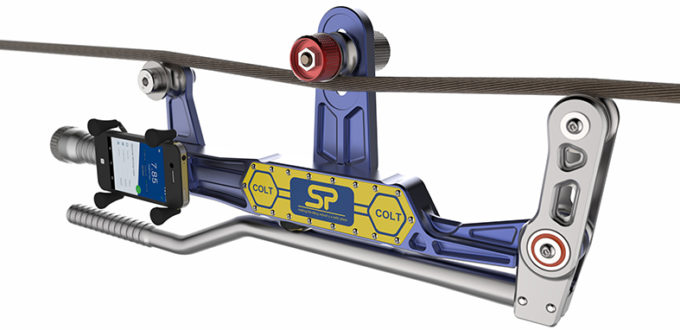

Tensology has used Crosby Straightpoint’s Clamp On Line Tensionmeter (COLT) to measure tension on eight .74 in (19mm) diameter ropes that lift a heavy, 50t capacity elevator at a major UK steel facility.

Tensology used the COLT, which measures tension up to 11,000 lbf (lb. force) / 5,000 kgf (kg force) and up to 1 in. / 25mm diameter, to verify that each of the eight newly installed ropes were under the same tension. Any variance would have created a safety issue when the elevator was returned to work delivering materials to different levels of the steel-making factory.

The COLT was clamped onto the pre-tensioned wire ropes and the tension was directly displayed. Tensology would previously have used a statimeter to complete the task.

Barrie Mordue, director at Tensology, a provider of specialist services related to wire ropes, said, “The facility issued a contract to replace the system of ropes that was part of a complicated reeving system, including counterweights and other components. The statimeter has been used for such applications for many years but it doesn’t provide a direct reading; users have to refer to a calibration graph. And it’s a two-person job to install it each time.”

Mordue singled out a state-of-the-art Bluetooth load monitoring app among the COLT’s standout features. The Bluetooth module transmitted tension data wirelessly to Tensology’s smart device running the app. Tension in each rope was measured and logged within a few seconds.

Mordue added, “The principle of the equipment is the same as more traditional methods but it is more user-friendly and efficient. The product makes contact with the wire rope at three points. Force is then applied to the rope at the center connection point while an auto-locking, magnetic handle mechanism secures it in place. Tension data is available in real time.”