We all have heard of rigging accidents, injuries, and even fatalities that may have been prevented if the rigging gear and/or slings had been properly inspected before the shift began or during its use. However, I still find individuals who are not aware of the need to perform an initial inspection.

What is the initial inspection?

This is an inspection done by a designated person who is required per ASME B30.9 (slings), ASME B30.10 (hooks), and ASME B30.26 (rigging hardware) before use of any new, altered, modified, or repaired sling or rigging hardware.

If you ordered new slings or rigging hardware, wouldn’t you want to ensure you received the right product, correct capacity, make sure it has no defects, plus ensure it functions properly before you make it a permanent part of your rigging inventory or release for use in the field?

If the product was altered, modified or repaired (assuming the manufacturer allows), ASME states that a qualified person must first inspect the sling or rigging hardware to verify it does not constitute a hazard if used in the field.

For the cranes, OSHA 1926.1412 (b)(1) also addresses the need for an initial inspection on the load hook after a repair or adjustment of equipment.

These are just a few of the things that come to mind when I think of the importance of making the initial inspection, a standard required procedure in the workplace. See OSHA and ASME for full details.

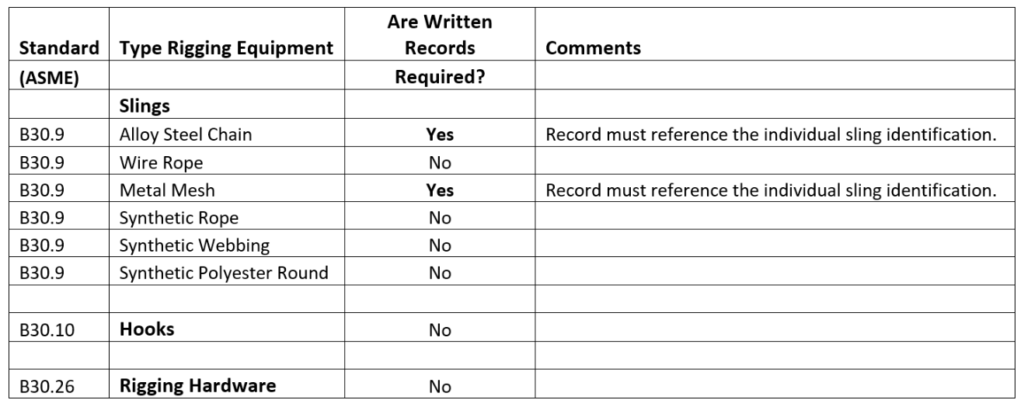

Written records

Did you know written records of the initial inspection are required per ASME B30.9 (2014) for alloy chain slings and metal mesh slings?

Rig safe!

– Danny

Danny’s Rigging Den is a blog series written by Danny Bishop, Crosby’s corporate director of value added training.