Danny Bishop compares two common types of wire rope slings.

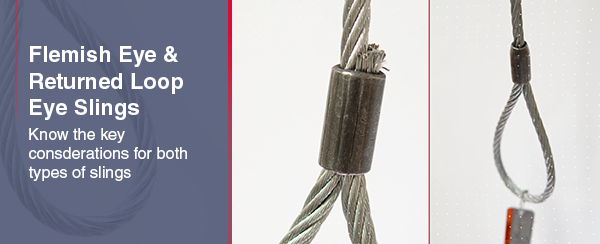

The two most common types of slings used in material handling applications using single part six-strand wire rope are the mechanical spliced Flemish Eye Sling and the mechanical spliced Returned Loop Eye Sling. Some people call the Returned Loop Eye Sling a Turnback Eye Sling.

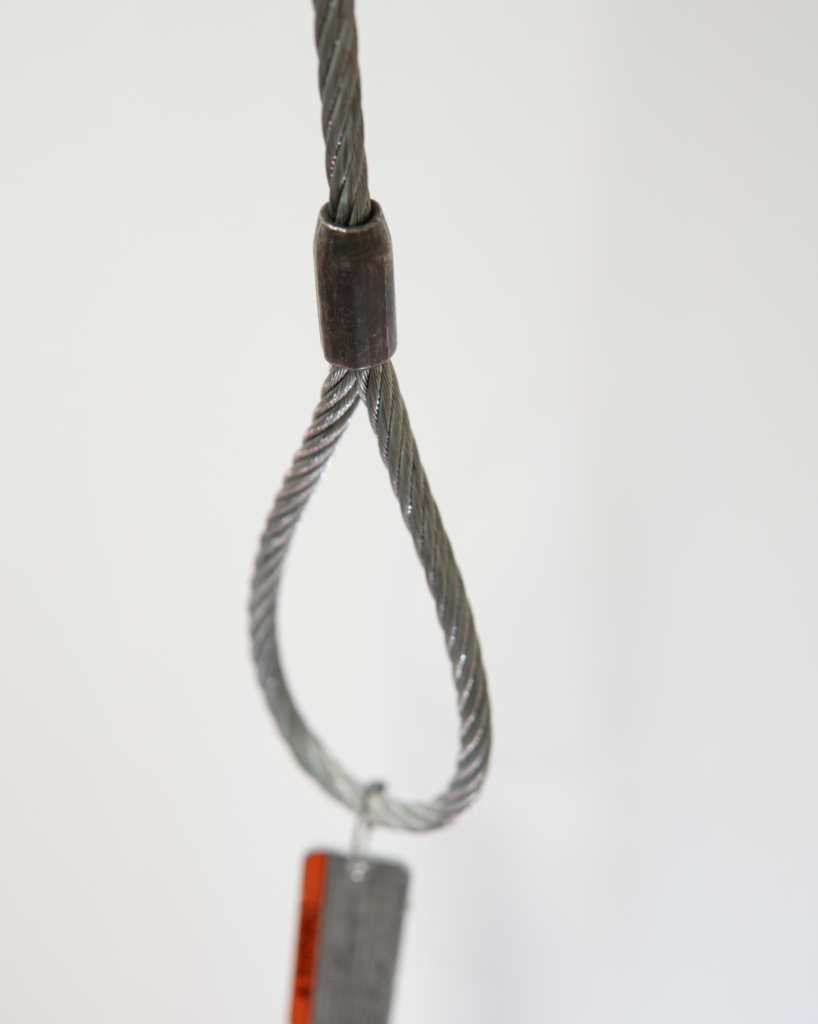

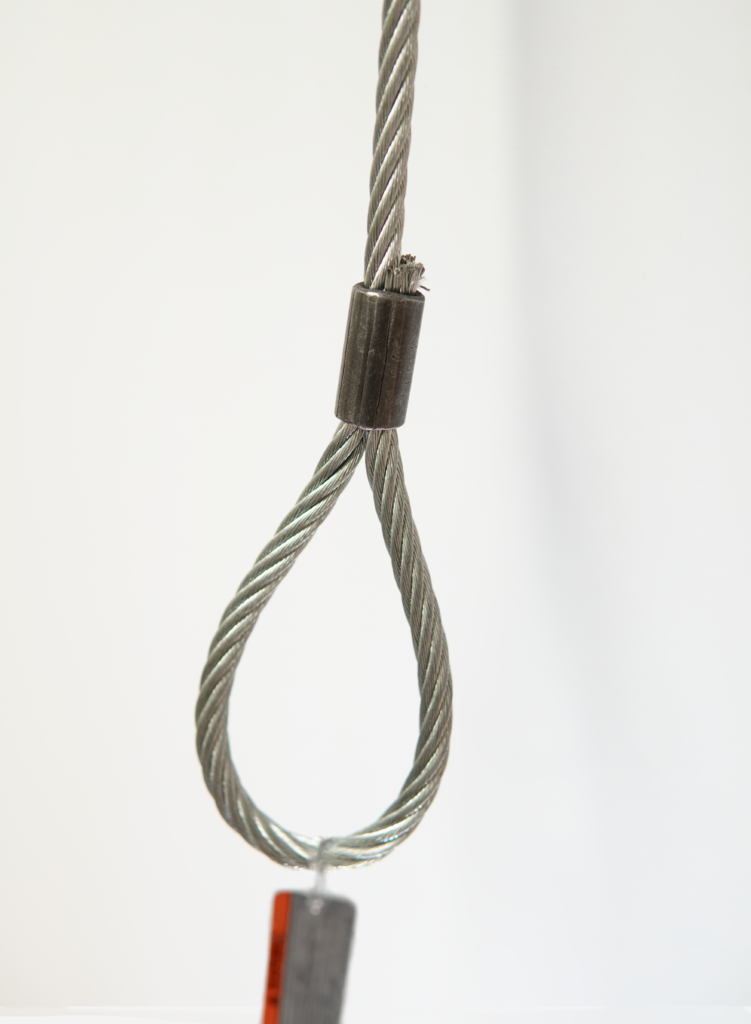

Visually, the two methods of termination look somewhat different when viewing next to each other. The Flemish Eye Sling normally has a swaged steel sleeve that is tapered down on one end, where a Returned Loop Eye Sling has one or more, straight non-tapered steel or aluminum sleeves. However, due to different fabrication methods and types of sleeves used by some sling manufacturers, the differences are not always so visually evident to the untrained eye.

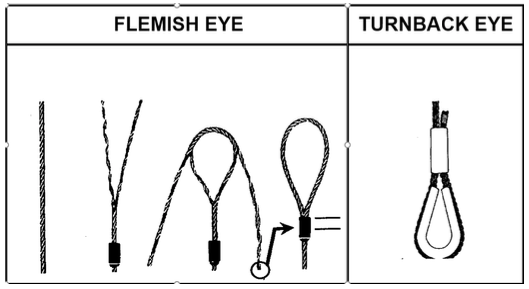

Although both types of slings use one or more metal sleeves swaged over the rope juncture, the fabrication method to produce each type of sling is different.

The Wire Rope Technical Board Sling User’s Manual describes the different fabrication methods as follows:

“The returned loop is fabricated by forming a loop at the end of the wire rope, sliding one or more metal sleeves over the short end of the loop eye pressing these sleeves to secure the end of the rope to the sling body.” (See picture below.) Having one metal sleeve at each eye is the most common practice.

“The Flemish eye is fabricated by opening or unlaying the rope body into two parts, one having three strands and the other having the remaining three strands and the rope core. The rope is unlayed to allow the loop or eye to be formed by looping one part in one direction and the other part in the other direction and laying the rope back together. The strands are rolled back around the rope body. A metal sleeve is then slipped over the ends of the splice and pressed (swaged) to secure the ends to the body of the sling.”

It is worth noting that the termination (splice) efficiency or the available strength of the wire rope sling after the fabrication method is complete is typically 90% or higher if fabricated correctly for each of the two methods described above, depending on the diameter of rope and other variables involved in producing the splice. Example of efficiency: A 94% nominal splice efficiency would mean you have 94% of the minimum breaking force (MBF) of the wire rope left after the termination or swaging method is complete.

Now let’s hit a few key considerations for both types of slings being discussed.

Flemish Eye Sling

- The Flemish Eye Sling is the more popular of the two-wire rope slings. This is mainly because of its rugged capabilities and ability to withstand abuse coupled with the fact that users prefer the backup splice under the swaged sleeve.

- Normally, a steel sleeve is swaged on a steel wire rope. Thus, no dissimilar materials are in contact with each other that can quicken corrosion attack.

- ASME B30.9 DOES NOT require a proof test for Flemish Eye Slings unless the user requires it.

- The Flemish Eye termination has a more streamlined profile that does not get as easily snagged on obstructions.

Returned Loop Eye (Turnback Eye Slings)

- Typically, these slings are quicker and cheaper to manufacture, excluding proof test time and costs.

- The strength of the sling depends entirely upon the integrity of the swaged sleeve. If the sleeve fails there is an immediate loss of load. Users in the field need to inspect the sleeves closely before each use.

- If aluminum sleeves are used on carbon steel wire rope, then the user may experience quicker deterioration due to the electrochemical reactions between the different metals. Saltwater and corrosive environments are particularly damaging.

- ASME B30.9 DOES require that all Returned Loop Eye Slings (Turnback Eye Slings) be proof tested by the sling manufacturer or a qualified person.

These are just some of the main differences between these two most common types of wire rope slings.

Rig safe!

Danny

Danny’s Rigging Den is a blog series written by Danny Bishop, Crosby’s corporate director of value-added training.