U-Bolt style wire rope clips are one of the most commonly used accessories in the world of rigging. They can be found in many lifting and non-lifting applications. They have the advantage of being a quick installation and allows adjustment of the wire rope.

Some common applications include winch lines, crane hoist lines, suspension cables, barrier cables, guy wires and many more. However, it is critical that the user know there are differences between a forged steel wire rope clip and a malleable cast iron clip.

The forged steel wire rope clip consists of a U-Bolt, two nuts, and a forged steel base, which is sometimes called the saddle.

The malleable cast iron U-Bolt style wire rope clip consists of the same components as just mentioned, except the clip base is not forged steel.

In fact, it is a malleable cast iron, and that can make a big difference in the performance and reliability of the clip. The malleable cast iron base does not have the desirable material properties of steel, or the beneficial grain structure that a forged base provides. Although, malleable cast iron products have their place in many applications, it is not the manufacturing process of choice for wire rope clip bases. This is especially true if the wire rope clip is used in a critical application.

It should be noted that some standards do not allow the use of malleable cast iron clips in critical applications. One example would be ASME B30.5 which states:

“Wire Rope Clips shall be drop-forged steel of single saddle (U-Bolt) or double saddle clip. Malleable cast iron clips shall not be used.”

ASME B30.26 also states, “Saddles shall be forged steel.”

Additionally, shortcuts in the production process of the bases may indicate there could be other shortcomings of the product. In some recent testing of malleable cast iron clips, it was found that U-Bolts fractured prior to achieving the recommended forged U-Bolt clip torque, on 2/3 of the assemblies tested.

Other things to consider:

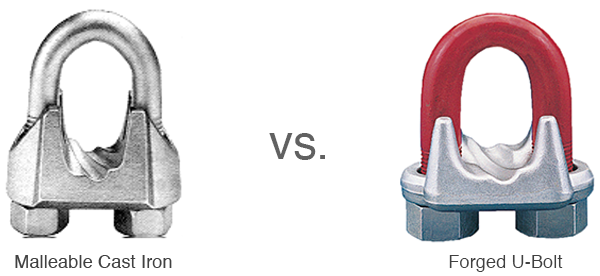

- Malleable cast iron clip bases are significantly different from forged bases in size, shape, and appearance. See comparison below of a Crosby forged clip base and a malleable cast iron clip both for ½-inch diameter wire rope.

- Malleable cast iron bases are inconsistent in strength and can have hidden defects.

- Malleable cast iron clips should not be used in critical applications.

Notice the significant difference in size, shape and appearance even though they are both for ½-inch diameter wire rope. Also, the Crosby clip exceeds ASME B30.26 marking requirements. No readable markings were found on the malleable cast iron clip.

Rig safe!

– Danny

Danny’s Rigging Den is a blog series written by Danny Bishop, Crosby’s corporate director of value added training.

No Comments Yet