How many times on the job site have you seen the riggers place more than two slings into one single point hook with no regard to the fact they may be tip loading, back loading, or even side loading the hook?

If you are like many of the people, your answer is, “Way too many times!”

Let’s review a few single point hook application facts that may be good to know when communicating to others, if you run into this practice in the field.

Hoist hooks are intended to be loaded in-line only. You never want to tip load, back load, or side load a hook. Keep the slings in the bowl of the hook.

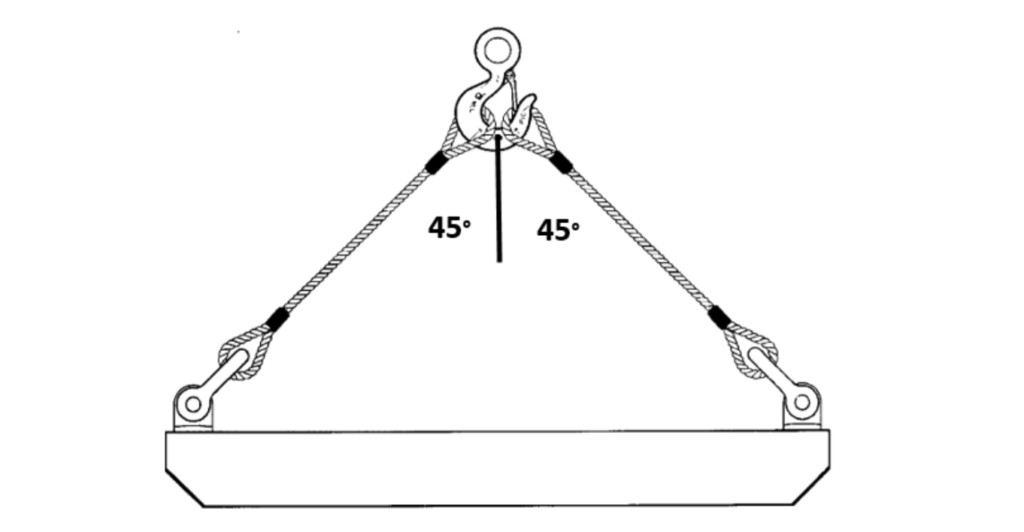

The maximum included angle which is allowed between two sling legs of a hook is 90 degrees. Keep the sling legs within 45 degrees from the center line of the hook. See graphic A below.

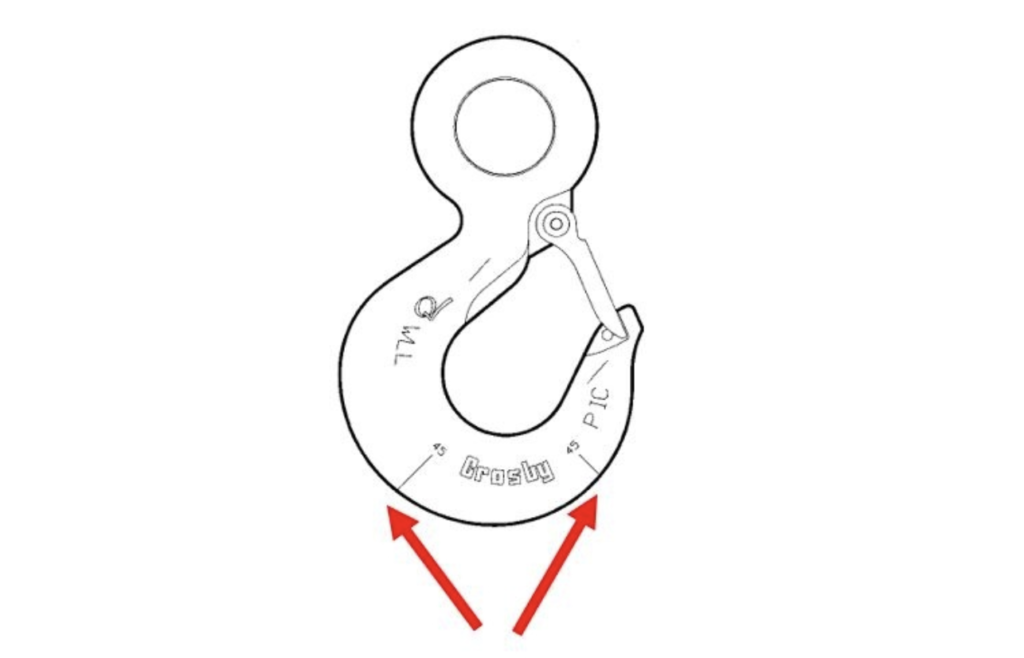

Crosby forged hooks have angle indicators to help you approximate your sling angles. See graphic B below.

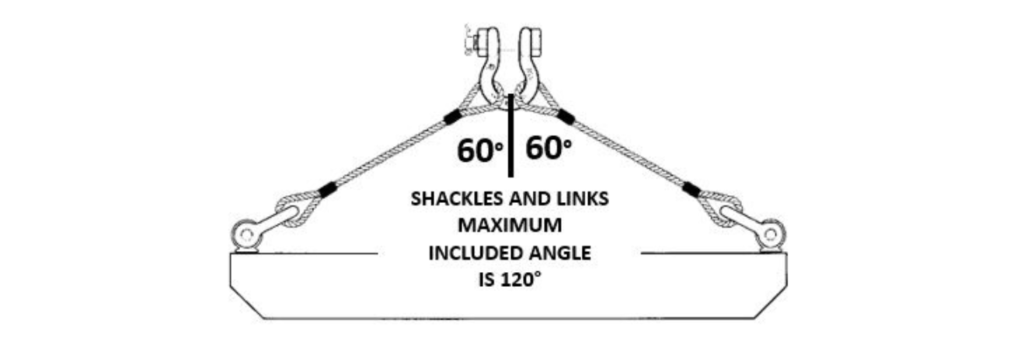

Information per ASME B30.10-1.11.1(e) : A collector ring, such as a link or shackle, should be used when more than two legs are placed in a hook or for angles greater than 45 degrees with respect to the hook center line.

The maximum included angle for Crosby shackles, links, and rings is 120 degrees (60 degrees either side).See graphic C below. These types of collector rings are also a good choice for achieving proper alignment of the slings in certain applications.

A shackle used to collect multiple sling legs must be a screw pin or bolt type shackle with bolt, nut, and cotter pin like shown above.

Rig Safe!

– Danny

Danny’s Rigging Den is a blog series written by Danny Bishop, Crosby’s corporate director of value added training.

No Comments Yet